From 2021, 70 employees will be pursuing a research approach in the University of Stuttgart’s approximately 8,500 square metre building on the Vaihingen campus located on the Allmandring that is also internationally unique: The goal is to develop novel nanophotonic quantum sensors to achieve groundbreaking advances in sensitivity, specificity and energy efficiency in sensor technology. Until now, no quantum sensors have been developed to such an extent that a technical application for them is emerging. Prof. Dr. Jörg Wrachtrup, whose 3rd Physics Institute will be responsible for the project, explains: “We will try to detect neuromagnetic fields, magnetic fields that are generated by neuronal activities such as brain activity. In order to study these very small magnetic fields, we have to work in an environment that does not itself create magnetic fields. That is only possible, of course, if there is no metal in the experiment room." The Stuttgart-based architectural office, hammeskrause architekten, was commissioned with the planning of the complex building.

Functional building concept

The special functional and building dynamic demands of the building were in the foreground of the layout planning. In longitudinal direction, the building is divided into the three sections head-end building, laboratory building and seminar building. The high-precision laboratories are located in the centre of the three-storey research building, where the building dynamic and shielding conditions for the experiments are best. Building applications causing vibrations, such as technical rooms, are located in the adjacent parts of the building. Astrid Karr from hammeskrause architekten explains: “At the heart of the building is the experiment hall with four high-precision measuring rooms. The entire building structure is constructed according to the shell principle in order to provide optimum protection for the testing equipment against external influences. In the middle is the testing facility that is protected by the surrounding concrete cube, the concrete cube is protected by the test hall and the test hall by the supporting functions, such as offices or laboratories.”

Supporting structure with high demands

Weiske + Partner from Stuttgart were commissioned with the structural planning for the building. Dr. Ulrich Breuninger explains: “The sensitivity of the experiments has a significant influence on the planning of the supporting structure. The design of the whole supporting structure and the dimensions of the ceilings and floor slabs are dictated by the high demands onvibration protection.” That is why the building parts with the clean rooms and the precision and high-precision measuring rooms were constructed on a one-metre thick and elastically bedded floor slab.

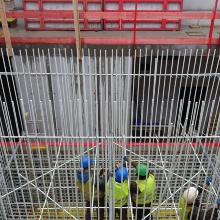

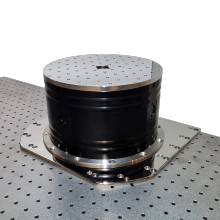

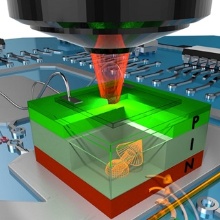

The planning and construction of the four high-precision measuring rooms represented the central challenge of the project. These rooms are located directly on the floor slab in the centre of the building. Concrete boxes with identical external dimensions – 7.60 metres by 5.80 metres – and different heights will be constructed: Boxes one and two are 9.9 metres high, boxes three and four have a height of 10.9 metres. The boxes for the four high-precision rooms are arranged in a common hall. In each of these is a concrete test table weighing 150 tonnes. The test tables have air springs for vibration absorption and are mounted on foundation bars which rest directly on the floor slab. This construction ensures maximum protection against vibration for the experiments performed in the high-precision rooms.

Due to the electromagnetic sensitivity of the experiments, all foundation blocks and test tables in the boxes are reinforced with glass fibre.

The surrounding walls of boxes two to four are of conventional semi-precast construction with steel reinforcement. Far higher demands are made on the shielding of the experiments against electromagnetic interference for box one: The outside of the complete box will have a cladding of metal alloy sheets. Magnetically conductive components are no longer possible inside this cladding. That is why the surrounding wall and the ceiling of the box will be built completely without steel reinforcement. In-situ concrete walls with formwork blocks reinforced with the glass fibre composite material, Schöck Combar, will be used. The ceiling is also made of in-situ concrete with glass fibre reinforcement.

High demands satisfied with Schöck Combar

Schöck Combar consists of corrosion-resistant glass fibres bonded with vinyl ester. As an alternative to steel that has been used as reinforcement material for decades, the coated reinforcement bar is characterised by the following properties as a technically advantageous solution: It has an extremely low thermal conductivity and is particularly strong and durable, non-flammable, corrosion-resistant, resistant to chemical attack, easy to machine and neither electrically conductive nor magnetizable - that is why Schöck Combar can be used to achieve electromagnetic decoupling of components to minimise electromagnetic interference and external influences. This material property is of central importance for use in a high-precision measuring room such as that at the ZAQuant. “Our work was helped by the fact that we were supported by Schöck from the very beginning. The Key Account Manager was intensively involved and advised and assisted us right from the preliminary discussions. We had exemplary cooperation with Schöck,” sums up site manager, Michael Westpfahl from Gottlob Brodbeck GmbH & Co.KG.

A research building for science

Prof. Dr. Jörg Wrachtrup from the University of Stuttgart: “One thing is sure: the combination of avoiding ambient vibrations and at the same time providing electromagnetic shielding for the test blocks is certainly unique worldwide. We spent many hours working with the planners and developing solutions." The ZAQuant is expected to be completed by the end of 2020 and scientists will be able to start their research from 2021.